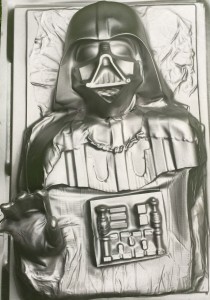

What would be more geek-fun then flash freezing Darth Vader with a metal alloy mixed with tibanna gas? We thought, not much! So, that’s what we did… At least  making something that looks like the Sith Lord suspended in Carbonite (See Star Wars – Return of the Jedi). We used an in-house process called vacuum forming to have a little fun.

making something that looks like the Sith Lord suspended in Carbonite (See Star Wars – Return of the Jedi). We used an in-house process called vacuum forming to have a little fun.

Vacuum forming works when you heat up a sheet of plastic in a jig and lower it over a positive form of the shape you want to create. As it lowers onto the mold, a vacuum table (like the reverse of an air hockey table) sucks the air out from under the plastic, forming it around the mold shape.  This is a really handy process for making cases, large panels, and packaging. Typically, we use it for work and paid projects, but when you have the toys, you might as well play every once and a while!

This is a really handy process for making cases, large panels, and packaging. Typically, we use it for work and paid projects, but when you have the toys, you might as well play every once and a while!

To create the form, we built a Vader look-a-like on a board using a mask, glove, Lego, Maker Studio parts, chain, some fabric, duct tape, a broken sled and some other odds and ends. Once we had the mold, we were able to vacuum form a sheet of plastic over Lord Vader on our vacuum forming machine. With a little paint touch up, we had Vader suspended in Carbonite-animation.

Enjoy this short video showing the process.

David Yakos is VP and Director of Creativity at Salient Technologies, Inc.